Margot Connell Recreation Center

Igniting active and healthy student lifestyles

- Client

- Boston College

- Location

- Chestnut Hill, Massachusetts, United States

- Size

- 244,000 square feet

- Status

- Completed

- LEED Silver Certified

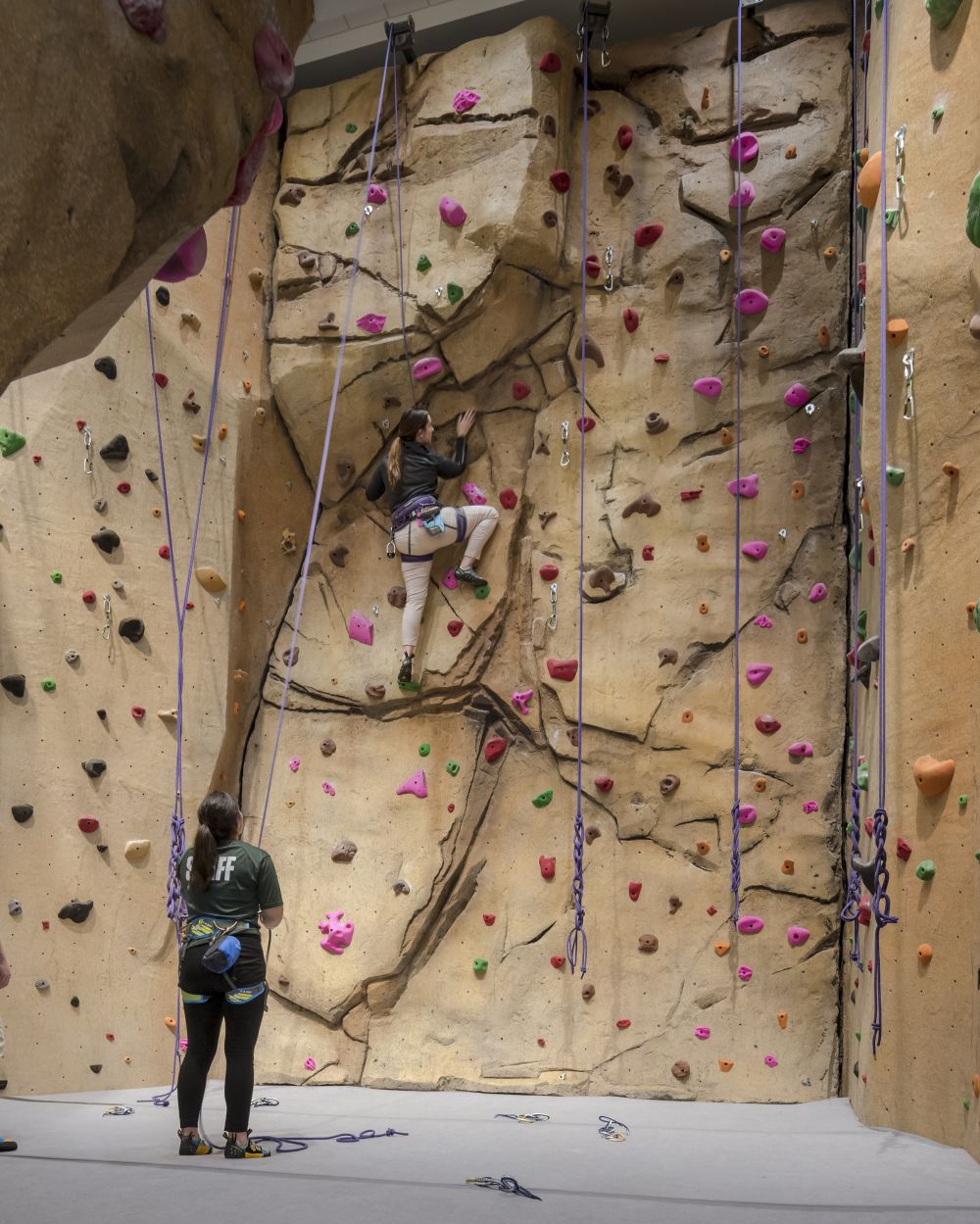

The Margot Connell Recreation Center is a truly unique facility both rooted in the tradition of Boston College’s collegiate gothic architecture and infused with leading-edge 21st century programming spaces and amenities. Standing four stories tall, the center is a beacon that redefines the future of fitness, recreation and wellness for the campus.

In line with Boston College’s principles around wellness, inclusivity and student life, the building is designed to welcome all through diverse programming, design choices and amenities. The building offers students and staff the opportunity to exercise, play sports, gather with friends and more. The design process was highly collaborative and united Boston College leaders, students, staff, design partners and builders.

The center is designed to reduce intimidation and promote inclusivity. Visual connections pervade the building and allow students to see across activity spaces and zones. This helps encourage students of all fitness levels and interests to use the building.

A central spine and stair fuel circulation and wayfinding throughout the building. It also inherently creates "soft" spaces for students to gather and socialize amidst the recreation areas. By every measure, the building works to promote healthy interactions.

Testimonials

Student impact

25%

increase in student recreation memberships the first semester after the building opened.

40%

increase in student activity and usage since the building opened to the campus community.