Is mass timber the solution to the massive carbon footprint of buildings?

Tim Costello, Eric Corey Freed, Brian Alesius, Julie Shaw and Scott Waddell

February 26, 2024

Social Sharing

In the dynamic realm of sustainable construction, mass timber has emerged as a transformative material — generating both excitement and challenges within the design and construction communities.

Mass timber is a category of structural systems that involves layering lumber into solid wood panels, beams and columns, offering a sustainable alternative to conventional materials. Its adaptability allows for diverse applications, from constructing wall panels, roofs and floors to entire structures. Navigating the complexities of integrating mass timber into building projects prompts a critical reevaluation of design principles, efficiency concerns and unique characteristics.

The traditional and more commonly used structural systems of steel and concrete offer several advantages, including speed and strength, but come with a major drawback: the associated carbon emissions from producing steel and concrete are a major source of greenhouse gas emissions contributing to the climate crisis. While the construction industry searches for methods to reduce these impacts, there are few low-carbon options available for steel and concrete. A scalable, code-compliant and zero-carbon alternative is urgently needed.

The design and construction industries are actively exploring methods to incorporate mass timber. Here are three compelling reasons why.

3 key benefits of mass timber

Low embodied carbon

Mass timber stands out as the only low-embodied carbon solution in construction for larger structures. Mass timber production produces significantly less carbon emissions compared to the energy-intensive processes involved in producing concrete and steel. Timber is also renewable. This translates into a greatly reduced embodied carbon footprint.

What is embodied carbon? According to the Carbon Leadership Forum, it's the greenhouse gas emissions arising from the manufacturing, transportation, installation, maintenance and disposal of building materials.

Furthermore, the construction process that utilizes mass timber is less energy-intensive. The lighter-weight timber components, especially when compared to heavy materials like concrete and steel, lead to reduced transportation and installation energy use. This efficiency has the potential to accelerate construction timelines.

Mass timber in action: California Institute of Technology, Resnick Sustainability Center

A makerspace for scientists, Caltech’s Resnick Sustainability Center will be a dynamic hub for critical research into the most pressing climate and sustainability challenges we face. The north and west elevations of the building consist of a mass timber structural grid shell supported by the primary concrete structure of the lab cores. The mass timber primarily supports the common circulation areas around the atrium and west side of the lab core and provides support for the organic curtain wall.

Biophilic design benefits

Mass timber seamlessly aligns with biophilic design principles, fostering a connection between the built environment and the natural world. The decision to expose timber structural elements — moving away from covering them with drywall — allows for an aesthetic experience that engages with natural elements. The natural quality of exposed mass timber transforms buildings into vibrant, healthy spaces.

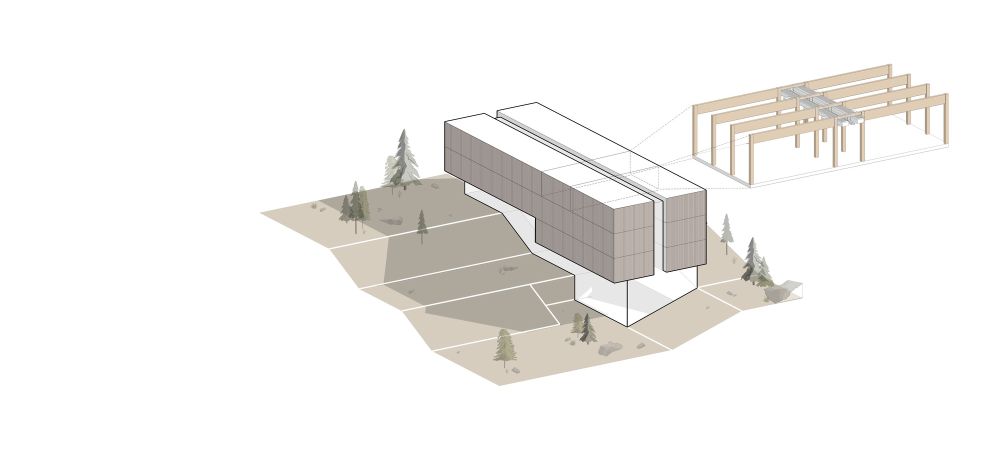

Mass timber in action: Oregon State University ‑ Cascades, Edward J. Ray Hall

Designed by SRG + CannonDesign, Edward J. Ray Hall provides a new learning environment for science, technology, engineering, arts, and math on the OSU-Cascades campus while creating a vibrant student hub with active interior and exterior spaces. The selection of mass timber for the building’s structural system reinforces OSU-Cascades’ robust commitment to sustainability with the use of a locally sourced renewable material and the low-carbon footprint associated with its production. The natural beauty of the timber structure is expressed in the building’s interior, creating a warm, inviting environment for students and faculty and visually connecting the building to the wood-clad exterior and the broader regional landscape.

Speed of construction

Since mass timber panels are prefabricated and then assembled on site, buildings made from mass timber take significantly less time to build than conventional structures — with some projects being completed 20-25% faster. The mass timber panels are designed for efficient assembly, which can also significantly reduce the number of workers needed on site, with the building components fitting together precisely like puzzle pieces.

Mass timber in action: 443 West, D’Youville University

As a home for D’Youville's new osteopathic medicine program, the construction of 443 West is on a critical path for the program to receive accreditation before the new students arrive. Selecting mass timber allows for quicker construction while helping the university achieve its goals for growth and expansion into the future. The project will be the first mass timber building in the Western New York Region. The carbon reduction in the structure is the equivalent of removing nearly 550 cars from the road for one year.

Mass timber challenges to overcome

Standardization

Efforts are underway to standardize the use of mass timber in construction. While inefficiencies exist, the industry is making strides on the engineering front to optimize efficiency. Standardization involves addressing design procedures, achieving uniformity across suppliers and refining the procurement process — which is often one of the most challenging aspects of a mass timber project.

Technical hurdles

The inherent nature of mass timber, exposed and free from coverings like drywall, presents both challenges and opportunities. Unlike steel, which is often covered for fireproofing, mass timber embraces exposure — though there are steps that can be taken to enhance its fire resistance, such as applying fire-retardant treatments and employing fire suppression systems. The exposure of wood also can pose challenges acoustically and in terms of vibration. Here again, these issues can be addressed if mass timber experts are engaged early in a project to guide you through these complexities.

Integration

Successfully employing mass timber requires an extremely holistic and integrated approach to design and construction with all teams working together from the start. Architectural teams often need to consider smaller than typical grid spacings to allow for efficient use of materials. Structural engineering teams need to ensure the integrity of the mass timber elements, considering factors such as load-bearing capacities, seismic performance and fire safety without diminishing the aesthetic value of exposed mass timber. Builders must also be involved from the start to provide their insights into the practical aspects of constructing a mass timber building, such as feasibility, procurement, logistics, cost-effectiveness and scheduling.

Become a mass timber pioneer with us

The journey towards mass timber is not just about materials, but a transformation of mindset and approach. Choosing mass timber demands a pioneering spirit because the design and construction process takes more creativity, grit and problem-solving than the traditional path. But it’s worth it. We are thrilled to be working on exciting mass timber projects across the country that serve as a testament to the possibilities that exist for designing and building a more sustainable future.